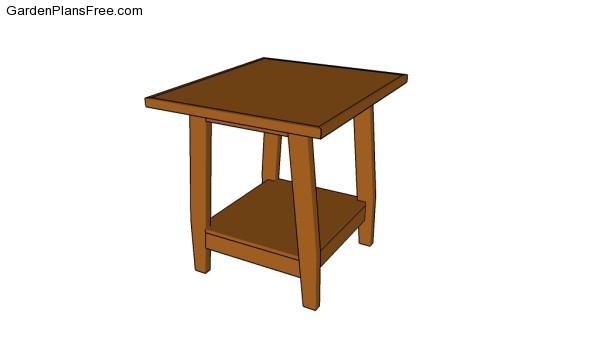

If you want to learn how to build a tools stand, we recommend you to pay attention to the instructions described in the article. There are so many projects you can build for your workshop, that we really encourage you to explore the rest of the plans featured on this website. We are pretty sure that you can get the job done in a professional manner, in less than one weekend.

First of all, we recommend you to choose the right tool stand plans for your needs and budget. Therefore, you have to plan everything from the very beginning and to invest in high quality materials, that are also weather-resistant. Cedar, pine or redwood are excellent choices, as they have a nice finish and are very durable. Cut the components at the right size by using a good circular saw and add waterproof glue to the joints, if you want to get a professional result.

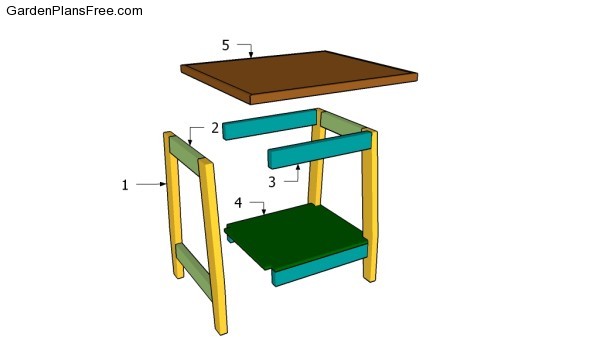

Tool Stand Plans

Building a tool stand

Materials

- 1 – 4 pieces of 2×4 lumber – 36″ LEGS

- 2 – 2 pieces of 2×4 lumber -21″, 2 pieces – 16 1/2″ SUPPORTS

- 3 – 4 pieces of 2×4 lumber – 24″ SUPPORTS

- 4 – 1 piece of 3/4″ plywood – 24″ x 27″ SHELF

- 5 – 1 piece of 3/4″ plywood – 31 3/4″ x 36″, 2 pieces of 1×2 lumber – 33 1/4″, 2 pieces – 37 1/2″ TABLETOP

Tools

- Hammer, Tape measure, Carpentry square

- Miter saw, Drill machinery, Screwdriver, Sander, Router

- Safety Gloves, Safety Glasses, Respiratory Mask

Time

- One day

Building a tool stand

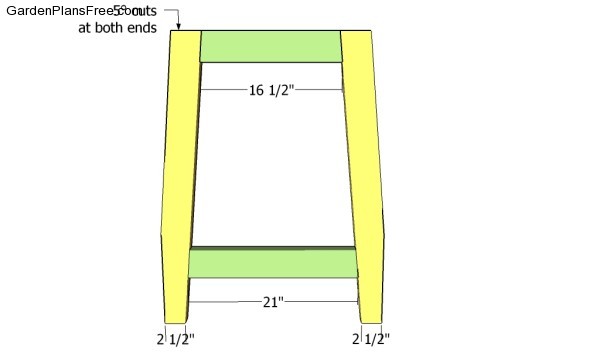

Building the frame of the stand

The first step of the woodworking project is to build the legs of the tool stand. Therefore, we recommend you to cut the pieces of 2×4 lumber at the right size, using the information shown in the plans. Use a good miter saw to cut both ends of the legs at 5 degrees and smooth the cut edges with a piece of sandpaper. Cut the supports and attach them to the legs with 2 1/2″ galvanized screws. Drill pocket holes at both ends of the supports before inserting the screws and adding glue to the joints.

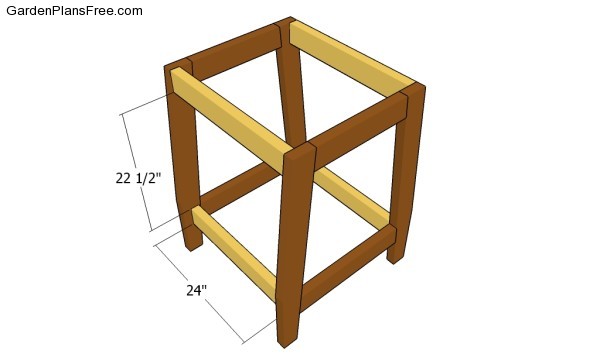

Attaching the supports

The next step is to install the supports between the two sides of the tool stand. Plumb both sides of the table with a spirit level before attaching the supports to the bottom and to the top of the table. Place a spirit level on top of the supports, to check if they are perfectly horizontal.

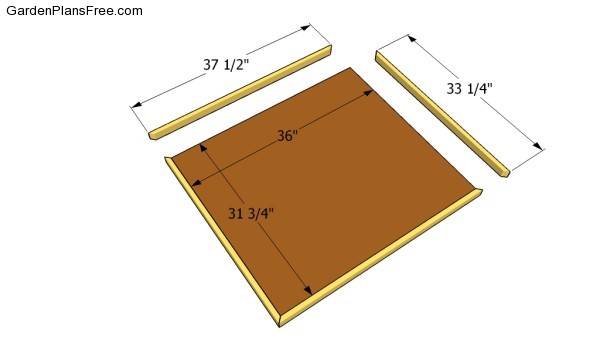

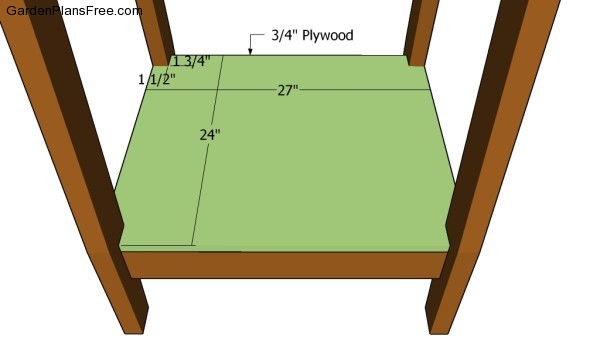

Building the tabletop

Building the tabletop is a straight-forward process, as it requires basic materials and common household tools. Cut the piece of 3/4″ plywood at the right size and attach the 1×2 trims to the edges, by using finishing nails and waterproof glue. align the components at both ends, if you want to get the job done in a professional manner.

Attaching the tabletop

Center the tabletop to the frame of the tool stand and secure it into place with galvanized screws. Drill pilot holes through the supports and insert 1 1/4″ screws into the tabletop, as shown in the image. Make sure the components are aligned properly, otherwise the tool stand won’t have a nice appearance.

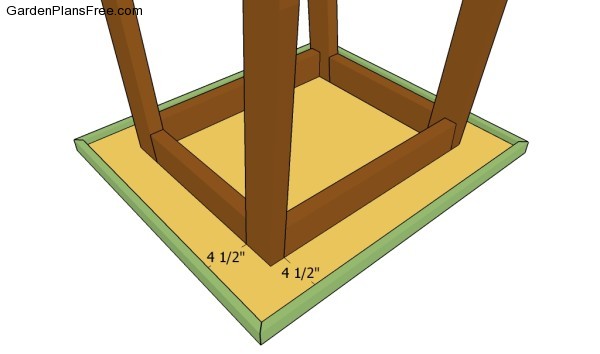

Fitting the bottom shelf

One of the last steps of the project is attach the bottom shelf to the supports, as shown in the plans. Cut several notches to the four corners of the 3/4″ plywood sheet, in order to fit into place easily. Drill pilot holes through the plywood sheet and insert 1 1/4″ screws into the supports.

Tool stand plans

Last but not least, you should take care of the finishing touches. Check if the components are secured into place properly and if the structure is rigid. Make sure there are no protruding screws or sharp edges that could injure you.

PRO TIP: Fill the holes with a good wood filler and smooth the surface with 120-grit sandpaper. Apply several coats of paint or stain over the components, in order to protect them from decay.

This diy project was about tool stand plans. If you have enjoyed the free project, we recommend you to share it with your friends, by using the social media widgets. LIKE us on Facebook if you want to be the first that gets our latest projects.