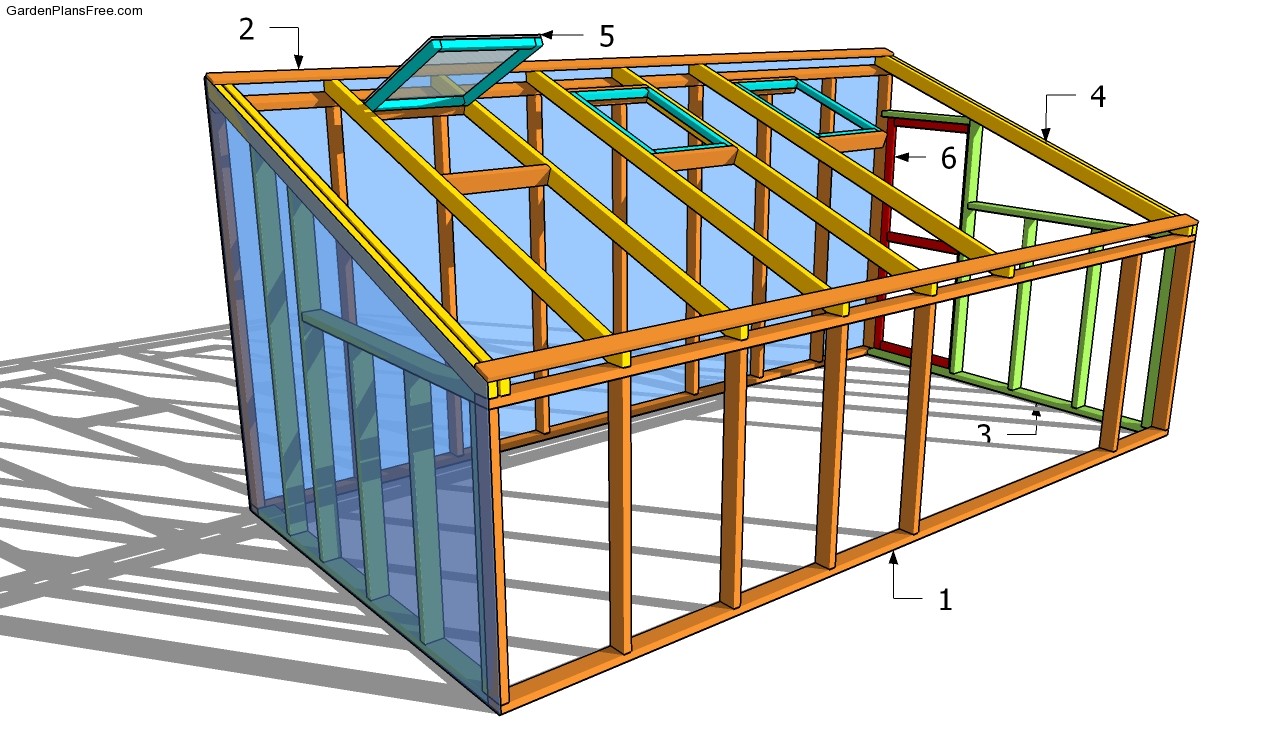

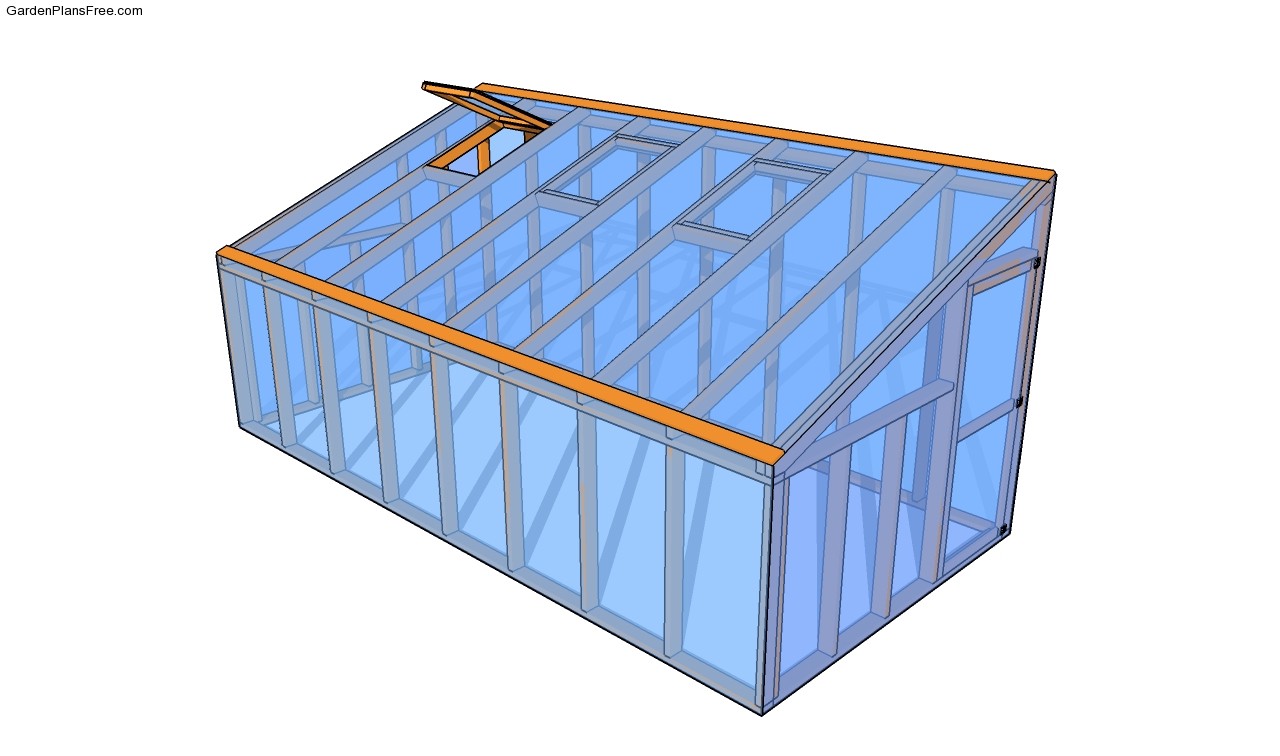

If you need a small space where to store you flower during cold days or you just want to grow fresh vegetables for your family, you should consider building a 8×16 lean to greenhouse. On one hand, you could attach the greenhouse the an existing building or you could place it on one corner of your property. Irrespective of your choice, it is essential to choose proper lean-to greenhouse plans. A lot more greenhouses plans HERE.

Use quality lumber for your construction, as the components should be straight and weather-resistant. From our experience, pressure-treated lumber or pine are good choice, provided they are in a good condition. Cover the wooden structure with polyethylene film or polycarbonate sheets, according to your budget and needs. In addition, build several vents between the rafters, in order to ventilate the plants properly.

Made from this plan

Building a lean to greenhouse

Building a lean to greenhouse

Materials

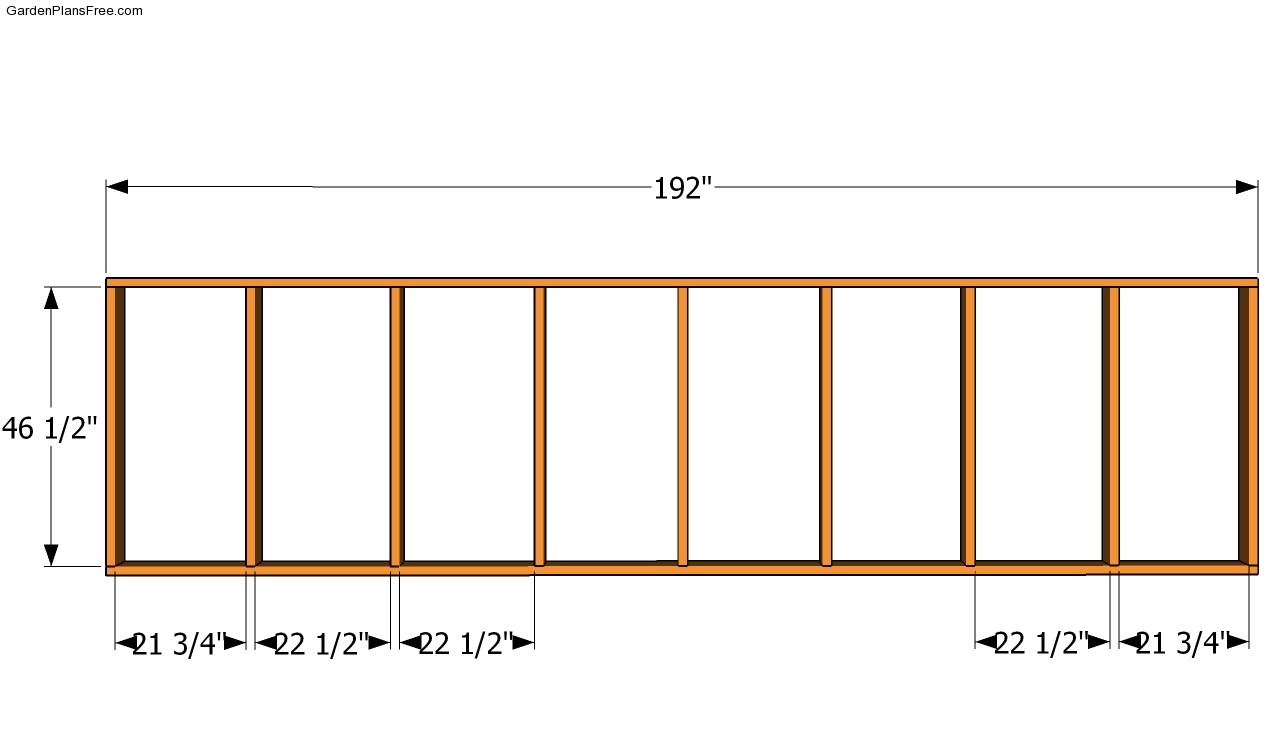

- 1 – 2 pieces of 2×4 – 192”, 9 pieces of 2×4 – 46 1/2″ SHORT WALL

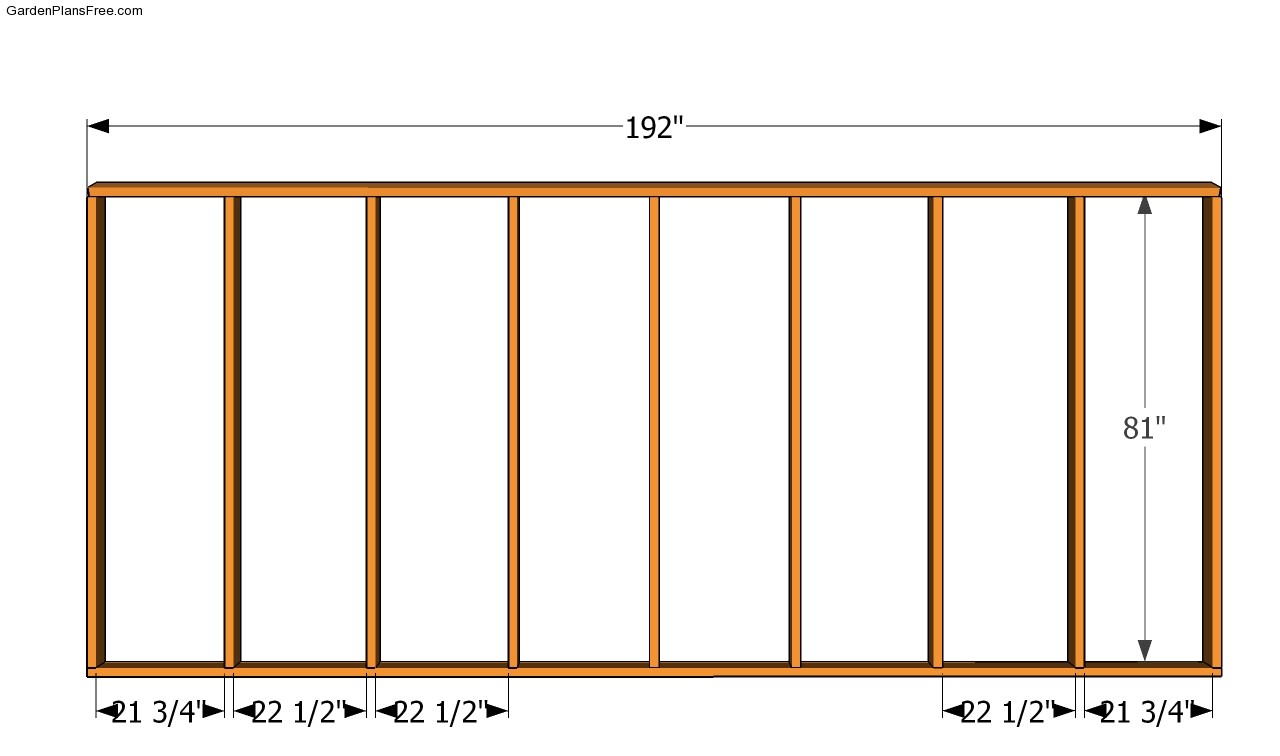

- 2 – 2 pieces of 2×4 – 192”, 9 pieces of 2×4 – 81″ TALL WALL

- 3 – 6 pieces of 2×4 – 46 1/2″, 2 pieces of 2×4 – 57 1/2″, 2 pieces – 70″, 1 piece – 30″ WALLS

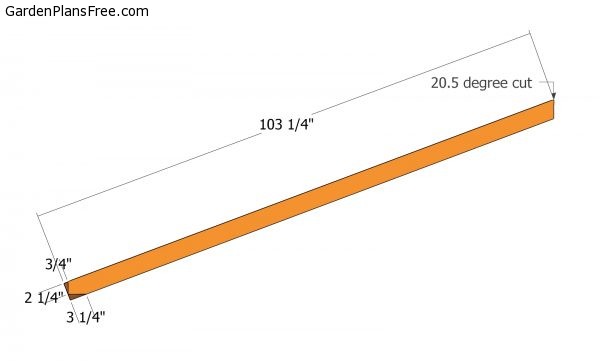

- 4 – 11 piece of 2×4 – 103 1/4″ RAFTERS

- 5 – 6 pieces of 2×4 – 22 1/2”, 6 pieces of 2×2 – 30, 6 pieces – 19 1/2″ VENTS

- 6 – 2 pieces of 1×3 lumber – 68 1/2”, 3 pieces of 1×3 lumber – 25″ DOOR

- 4 pieces of 2×4 lumber – 16 ft

- 27 pieces of 2×4 lumber – 8 ft

- 11 pieces of 2×4 lumber – 10 ft

- 5 pieces of 2×2 lumber – 8 ft

- 4 pieces of 1×2 lumber – 8 ft

- 3 1/2″ screws

- 2 1/2″ screws

- 1 5/8″ screws

- greenhouse film

- automatic vent opener

- door hinges

- door latch

- hinges for vents

Tools

- Hammer, Tape measure, Carpentry square

- Miter saw, Drill machinery, Screwdriver, Sander, Router

- Safety Gloves, Safety Glasses, Respiratory Mask

Time

- One day

Lean to greenhouse plans

Small wall plans

The first step of the project is to build the side walls of the lean to greenhouse. As you can easily notice in the image, you need to use 2×4 lumber and 3″ galvanized screws. Drill pilot holes trough the bottom and top plates and insert 3″ screws into the studs. Place the studs every 24″ OC, in order to support the weight of the structure properly.

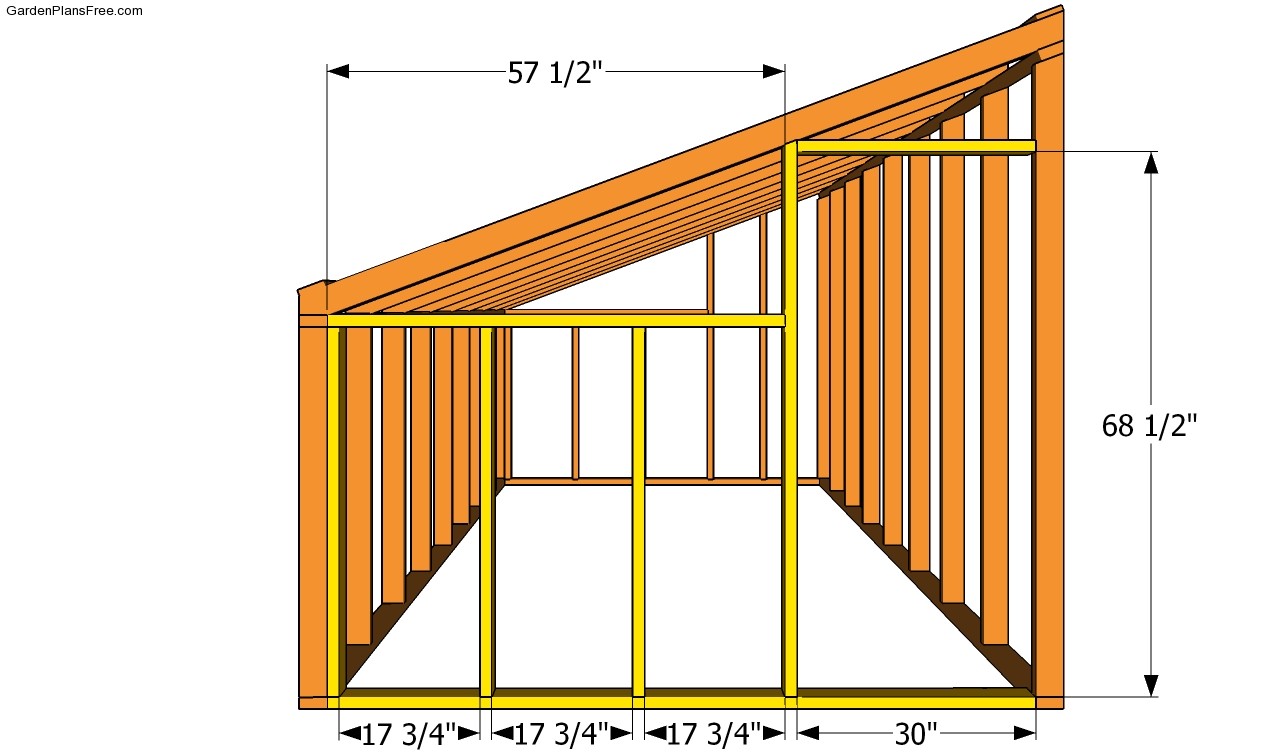

Building the large wall

Next, you need to build the opposite wall of the greenhouse, in the same manner described above. In addition, you need to cut the top of the studs at 20.5º or at the angle you want he greenhouse to have. In addition, place the top plate to the frame with great care and align it at both ends, if you want to get the job done as a professional.

PRO TIP: Check if the corners are right-angled before continuing the project with the next steps. Place the frames into chosen location and secure them temporarily with 2×4 braces. Measure the diagonals of the layout and make cure they are perfectly equal.

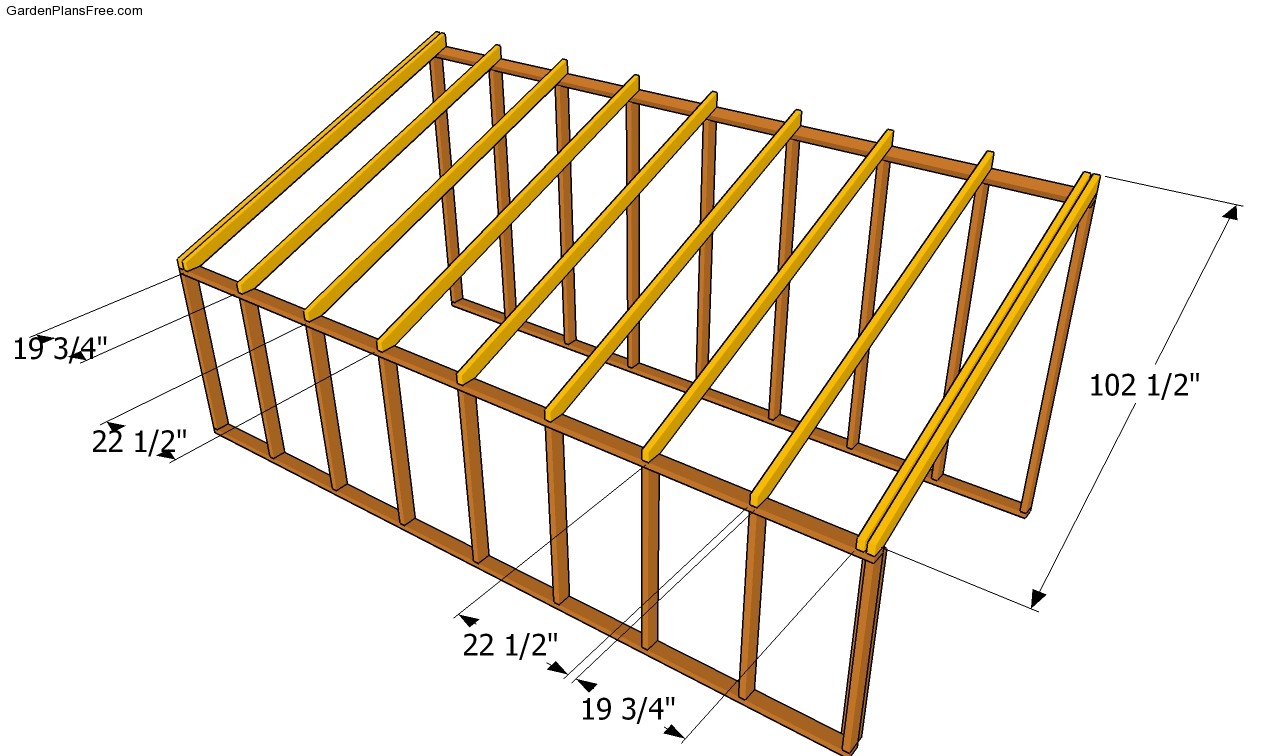

Build the rafters from 2×4 lumber. Make the cuts to the beams, as shown in the diagram.

Fitting the rafters

Place the rafters to the frame of the greenhouse, every 24″ OC, and lock them to the top plates with 3 1/2″ galvanized screws.

PRO TIP: Drill pilot holes into the rafters before inserting the screws, to prevent the wood from splitting. In addition, plumb the rafters with a spirit level, if you want to get a professional result.

Back wall plans

The next step is to build the back wall of the greenhouse. As you can see in the image, you need to use 2×4 lumber. Cut the components at both ends and lock them into place with galvanized screws. Use a spirit level to check if the studs are plumb and if the plate is horizontal.

Front wall plans

Building the front face is not difficult, if the right plans are used. As you can notice in the image, you should let enough space for a large door. Framing the door should be done as in the plans, as to provide a good support to the constructions.

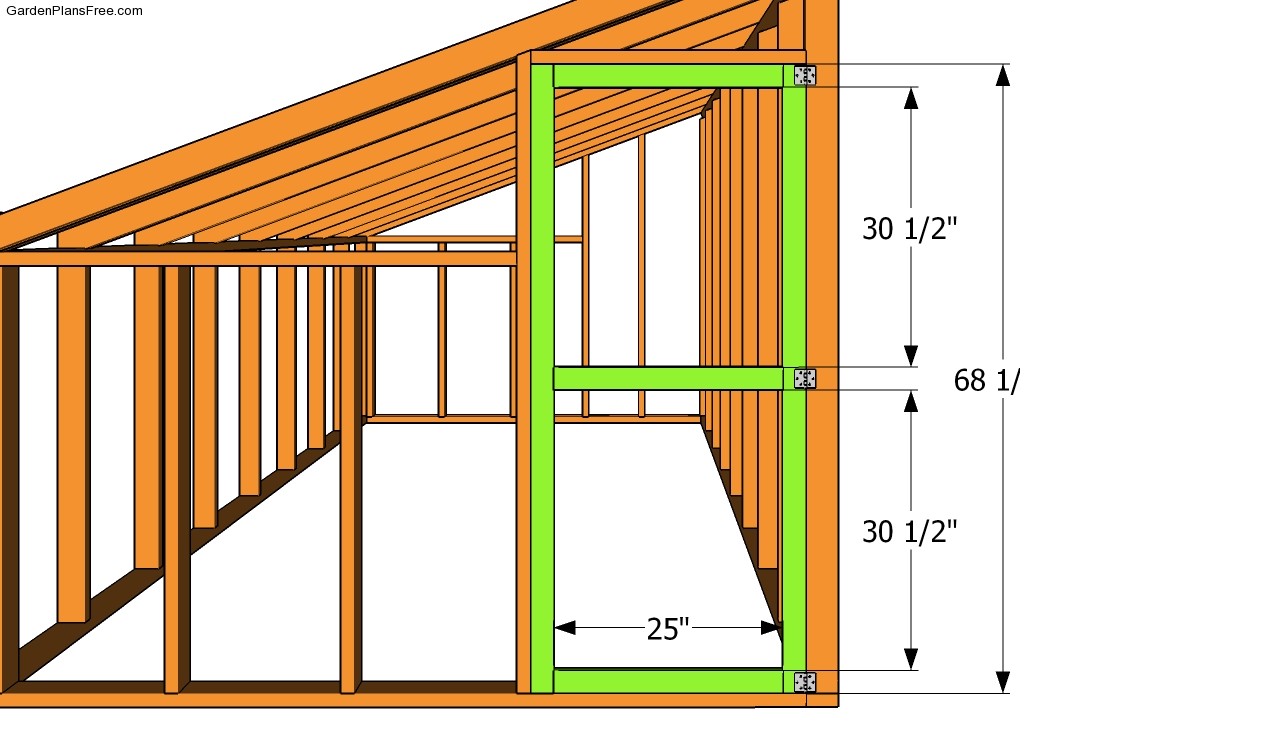

Building the door

Building a door for the greenhouse is a straight forward process, if the right plans and tools are used. Build the frame of the door using 1×4 lumber and lock them together with pocket screws. Drill pocket holes at both ends of the small components and secure them to the sides with 1 1/4″ screws. Attach the door too the frame with several metal hinges, after making sure it is perfectly level and aligned properly.

PRO TIP: There should be about 1/8″ clearance space between the door and the frame, in all directions, otherwise the door won’t open properly.

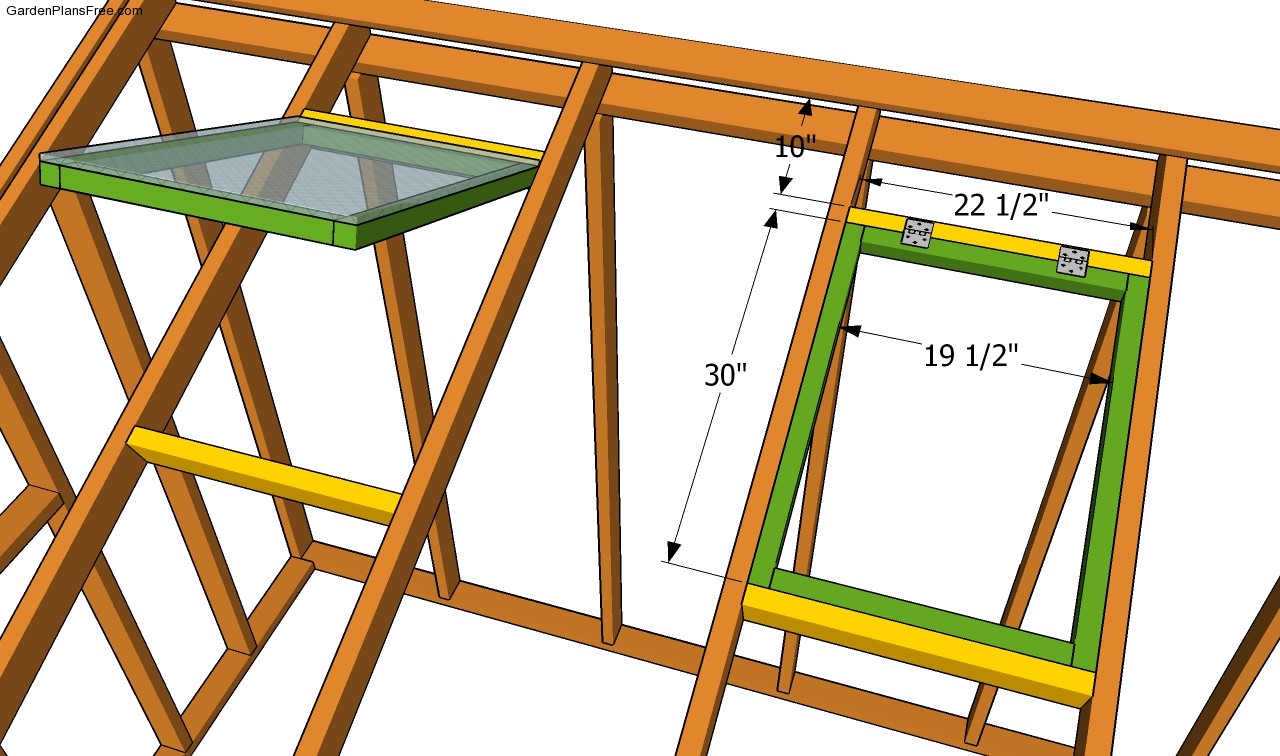

Building the air vents

If you want to ventilate the greenhouse properly, you should build several vents between the rafters. Build the frame of the vents from 2×2 lumber, as in the image, and lock them to the roof with metal hinges. Place a piece of polycarbonate to the frame of the vent. In addition, you could install a vent opener, in order to automate the process. When the temperature inside the greenhouse exceeds a certain level, the brace will open the vent to let the cold air to get in.

Lean to greenhouse plans

Last but not least, you should take care of the finishing touches. Therefore, we recommend you to check if the components are locked into place properly and if the walls are perfectly plumb. Make sure there are no protruding screws or sharp edges that might damage the polyethylene foil.

PRO TIP: Stretch the film over the structure of the greenhouse and lock it into place with 1×2 strips of wood. Secure the 1×2 components to the rafters, using 1 5/8” wood screws.

This diy project was about lean-to greenhouse plans free. If you have enjoyed the free project, we recommend you to share it with your friends, by using the social media widgets.

33 comments

It would be nice to know the overall dimensions of the Lean to Greenhouse such as 10 x 12.

Thanks

It’s a 8×16 greenhouse.

Am going to build this one and 4×4 treated frame with i.e. 2×6 or like flooring for drainage via plywood or if you have other idea for it will not be on the ground. Looking for flooring options team.

the “film” that’s briefly mentioned at the conclusion of the article is not listed in the materials section at the start of the project. what is the film, its thickness in millimeters and where do you buy it? attaching procedure is perfunctory at best.

Greenhouse plastic. You find that in most stores. The thickness differs according to the climate and budget.

Can you make me the same plans with different wall heights?

Comical, the question’s people ask when the information was provided, they just failed to read. Btw, thanks for the plans. I used it , adjusted it a tad so it was 10 x16 instead with 96 “( 8 foot for those who can’t convert yourself ) head room.

That sounds great. I would love to see your project. You can send the pics here: http://gardenplansfree.com/contact/

I have adapted this design to my sloping garden, changed dimensions a bit too. I found it very useful as I am not a tradesman but still was able to do it with help of these drawings. It would be advantageous if materials.drawings included lengths in metric. I will send pics when I am done! Cheers!

Looking forward to seeing your project.

Would you mind breaking down the materials a bit? I am having a hard time figuring out how many 2.x’s, etc. We intend to build this almost exactly as is but using the sheets instead of the plastic. Thank you so much!

I’ve added a quick materials list. Let me know how your greenhouse comes out!

Thanks for providing these plans. Can you clarify whether this could be built as a stand-alone structure? Or would the engineering need to be beefed up to stand on its own? Cheers.

It can be attached or it can be free standing.

Is it possible to get plans and material list to build a custom size lean to greenhouse. We don’t have the room to go 8 ft deep so it would have to be 7.5 and we would it to be 11 ft wide and I’m not sure of the height that the roof slopes to and need to know that. Thanks

Hi Thomas

Can you tell me what lumber/method is used to attach the structure to the side of a building?

Can you give me what lumber I would need for a 10×20 and also the plans

Would this be do able free standing?

Perhaps built on a 4x4post floor frame that was somewhat attached to an anchor cinder block

Is it possible to print this out?

You have to buy the pdf plans for that, see GET PDF PLANS button at the end of the article

Hi my name is Dyann. Would you give me what I need for a 12x 21 greenhouse and 12ft high and at the low point at least 6ft. Our plastic sheeting come in 3ft wide only and we need a big pitch because in Ontario we get a lot of snow. Thank you

Resa here, I never built anything much but I want to build this. I think I can do this. I tried building a hoop house last year. It stood over the winter but still not durable enough because it was made out of PVC, I think this will do fine. Hope this will be fine for my space 8 x 12.

This is a 8×16 greenhouse. It won’t fit your space, unless you make modifications.

I have concrete outside patio and would like to build lean on greenhouse. Is it possible to use glass windows instead of sheet with this plan? Woul frame support the weight of glass all over the greenhouse? Please do let me know.

Thanks Thomas for putting such a wonderful piece of information on internet.

Regards

Thank you for the concept, we are building this starting next weekend. A question: how are the windows and roof separated as to the film. Just cutting the film around the windows? How is it sealed?

Can I hire you to do a custom lean-to design (6 by 12)? I have 36″ by 61 and 41 by 61 windows.

Thanks for the plans and materials list on this lean-to! I’ve been working on a plan for a couple days trying to work out the details and cuts and this will help make it go a little more quickly. The changes we will make is the door will be in the middle of the tall (front) wall and it will sit in 4×4 treated beams. We may have to cut down the length to 10 or 12 feet depending what the HOA approves and space.

Again, Thanks!!!

this is great, but I didn’t see any details about the footing/foundation of the greenhouse. What is fastening it to the ground?

Lateral stability does not appear to be considered in this design except for what small amount that might be gained from the fasteners (3-1/2″ screws?). If wind poses a problem in the project area, one may want to consider diagonal bracing in the corners either using 2×4 material or 1/2″ exterior plywood panels.

Don’t know if this has been asked, but, how are those windows supposed to be leak proof?

We get heavy storms in Oklahoma, and need better ideas on the vent windows of possible.

Thanks!

A 5 foot doorway? 🤣

5 ft 8 1/2″ + 1 1/2′ (bottom plate) = 70″

What a service for DIY enthusiasts!