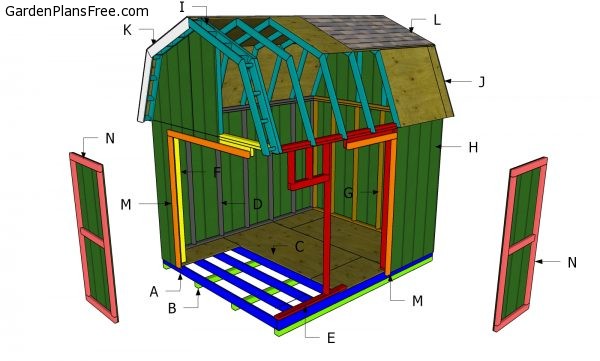

If you want to learn more about 10×12 gambrel shed plans you have to take a close look over the free plans in the article. This is my latest shed design and I chose to be a about a gambrel shed. The shed features a 10×12 base and comes with double 6 ft front doors and a 3 ft side door with a window. Remember to read the local codes before starting the project and to comply with the local regulations. The codes differ from one area to another, so it is safer to read them thoroughly.

If you want to get the job done in a professional manner, we recommend you to plan everything with attention, as to prevent costly mistakes and to build a professional garden project. Invest in high quality materials, such as cedar, pine or redwood, as the bench will be exposed to all kinds of weather. Apply a few coats of paint over the components, to enhance their appearance and to protect them from bad weather.

10×12 Shed Plans – Gambrel Shed – PDF Download

Building a 10×12 barn shed

Materials

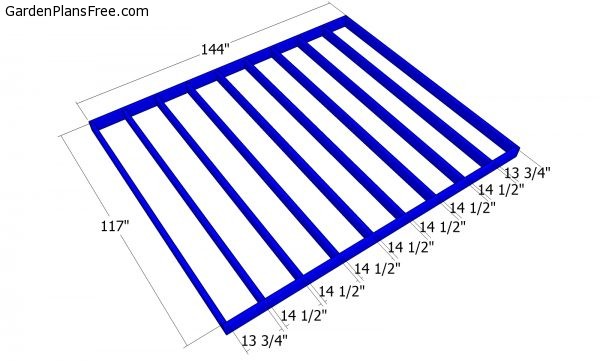

- A – 2 pieces of 2×6 lumber – 144″ long, 10 pieces – 117″ long FLOOR FRAME

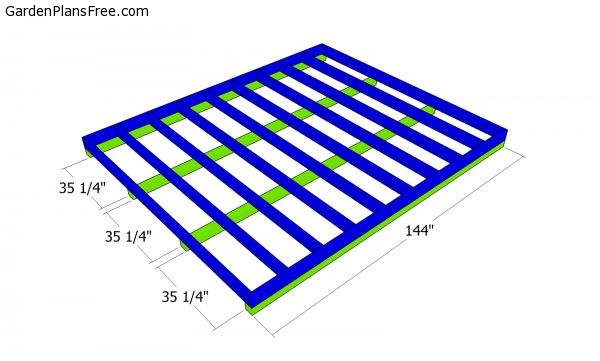

- B – 4 pieces of 4×4 lumber – 144″ long SKIDS

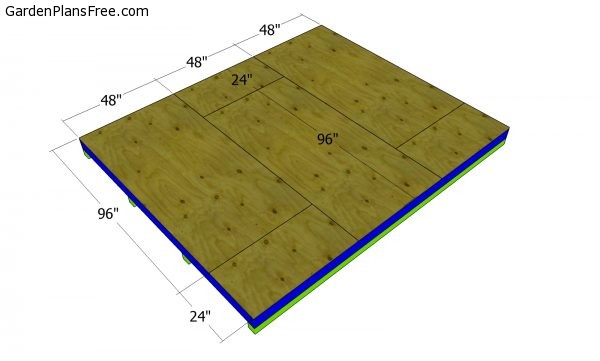

- C – 3 pieces of 3/4″ plywood – 48″x96″ long, 3 pieces – 24″x48″ long FLOOR

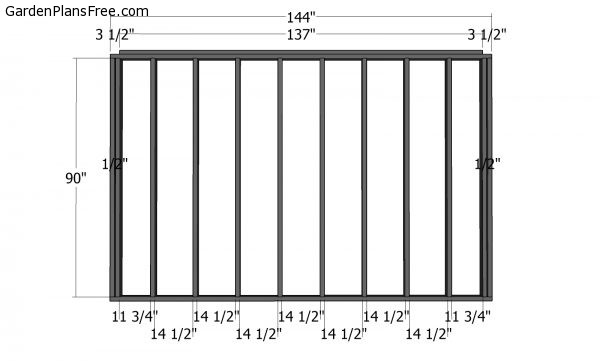

- D – 2 pieces of 2×4 lumber – 144″ long, 1 piece – 137″ long, 12 pieces – 90″ long SIDE WALL

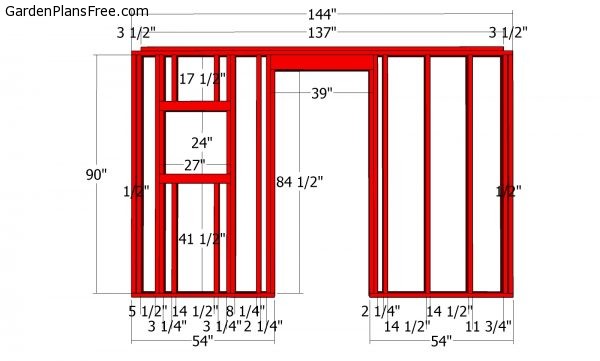

- E – 2 pieces of 2×4 lumber – 144″ long, 1 piece – 137″ long, 12 pieces – 90″ long, 2 pieces – 54″ long, 4 pieces – 41 1/2″ long, 2 pieces – 24″ long, 4 pieces – 17 1/2″ long, 2 pieces – 84 1/2″ long, 2 pieces of 2×6 lumber – 39″ long SIDE WALL WITH WINDOW

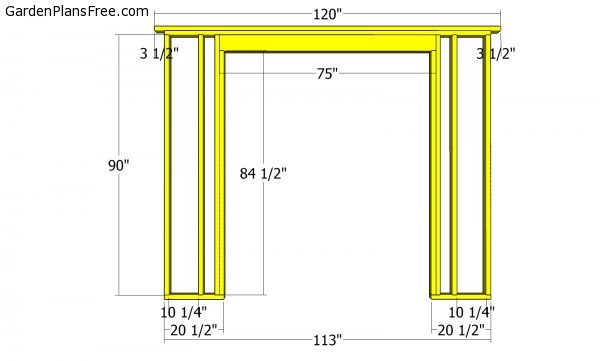

- F – 2 pieces of 2×4 lumber – 20 1/2″ long, 1 piece – 113″ long, 2 piece – 120″ long, 6 pieces – 90″ long, 2 pieces – 84 1/2″ long, 2 pieces of 2×6 lumber – 75″ long FRONT WALL

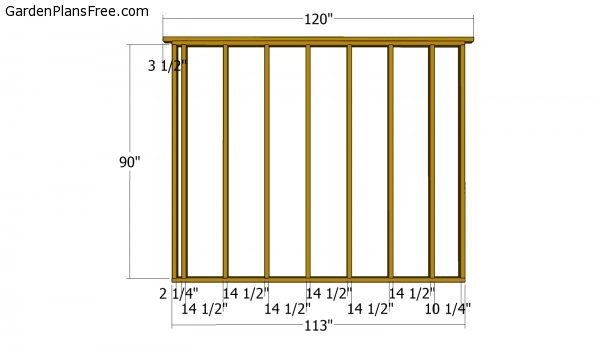

- G – 2 pieces of 2×4 lumber – 120″ long, 1 piece – 113″ long, 9 pieces – 90″ long BACK WALL

- H – 10 pieces of T1-11 siding – 48″x96″ long, 1 piece – 24″x96″ long, 1 piece – 7″x24″ long, 4 pieces – 48″x57 1/4″ long, 2 pieces – 24″x62 1/4″ long SIDING

- I – 40 pieces of 2×4 lumber – 48″ long, 4 pieces – 52 3/4″ long TRUSSES

- I – 16 pieces of 2×4 lumber – 48″ long, 32 pieces – 4 1/4″ long BLOCKINGS

- J – 8 pieces of 1/2″ plywood – 8″x48″ long, 4 pieces – 48″x96″ long, 4 pieces – 48″x48″ long ROOF

- K – 8 pieces of 1×6 lumber – 48 1/2″ long TRIMS

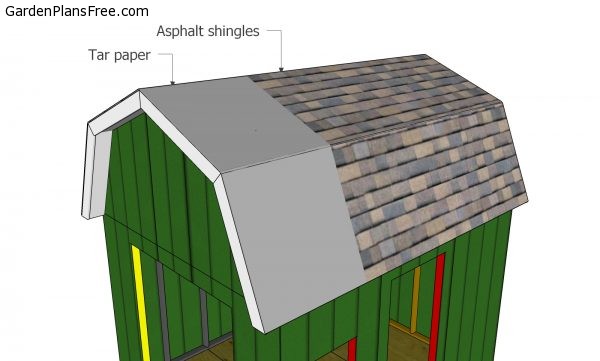

- L – 250 sq ft of tar paper, 250 sq ft of asphalt shingles ROOFING

- M – 4 pieces of 2×4 lumber – 89″ long, 1 piece – 43″ long, 1 piece – 79″ long JAMBS

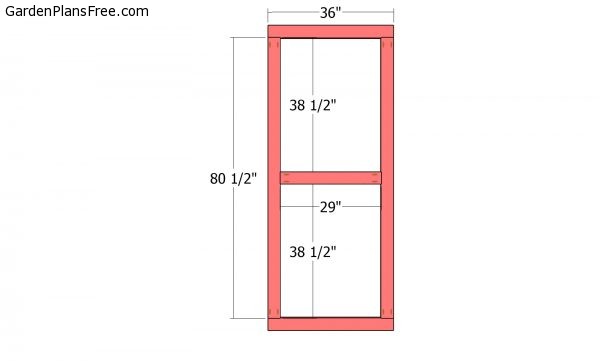

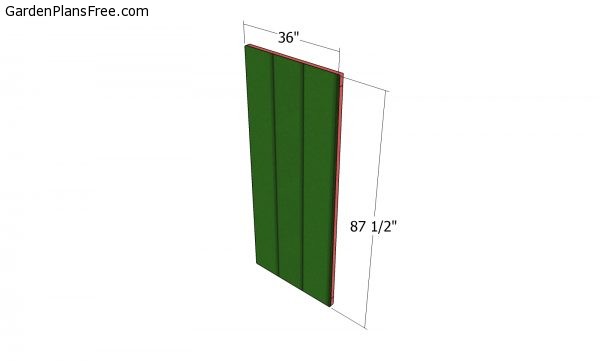

- N – 1 piece of 5/8″ T1-11 siding – 36″x87 1/2″ long, 2 pieces of 2×4 lumber – 36″ long, 2 pieces – 80 1/2″ long, 1 piece – 29″ long 3xDOOR

- 2 pieces of 2×6 pressure treated lumber – 12 ft

- 10 pieces of 2×6 pressure treated lumber – 10 ft

- 4 pieces of 4×4 pressure treated lumber – 12 ft

- 4 pieces of 3/4″ plywood – 4’x8′

- 5 pieces of 2×4 lumber – 12 ft

- 5 pieces of 2×4 lumber – 10 ft

- 98 pieces of 2×4 lumber – 8 ft

- 3 pieces of 2×6 lumber – 8 ft

- 15 pieces of 5/8″ T1-11 siding – 4’x8′

- 8 pieces of 1/2″ plywood – 4’x8′

- 4 pieces of 1×6 lumber – 8 ft

- 1 piece of 1×4 lumber – 10 ft

- 250 sq ft of tar paper, 250 sq ft of asphalt shingles

- 1 1/2″ structural screws

- 1 5/8″ screws

- 2 1/2″ screws

- 3 1/2″ screws

- 2″ nails

- wood glue, stain/paint

- rafter ties

- door hardware kit

Tools

- Hammer, Tape measure, Carpentry square

- Miter saw, Drill machinery, Screwdriver, Sander, Router

- Safety Gloves, Safety Glasses, Respiratory Mask

Time

- One week

STEP 1: Building the shed floor

Building the floor frame

The first step of the project is to build the floor frame for the 10×12 garden shed. As you can see in the diagram, you need to cut the joists from 2×6 lumber. Lay the components on a level surface and align the edges flush. Drill pilot holes and insert 3 1/2″ screws to assemble the frame. Make sure the corners are square. Place the joists every 16″ on center. You can use joist hangers alternatively, and 1 1/2″ structural screws.

Skids

Select the location for large storage shed and remove the vegetation layer. Spread a 2-3″ layer of gravel under the shed floor, so you can protect the floor from moisture. Next, lay the 4×4 skids under the floor frame and lock them together with rafter ties and 1 1/2″ structural screws. The skids will lift the floor frame from the ground to protect the components from moisture. Use pressure treated lumber for the floor frame, as the boards will be exposed to moisture.

Floor sheets

Fit the 3/4″ tongue and groove plywood sheets to the floor frame and align the edges flush. Leave no gaps between the sheets and secure them into place, every 8″ along the joists, using 1 5/8 screws. Invest in pressure treated plywood if you want extra durability.

STEP 2: Building the shed wall frames

Side wall frame

The next step of the project is to build the wall frame for the plain side wall. Cut the components at the right dimensions and drill pilot holes through the plates. Insert 3 1/2″ screws to lock the plates to the studs. Make sure the corners are square. Place the studs every 16″ on center. Notice the double studs placed at both ends of the wall.

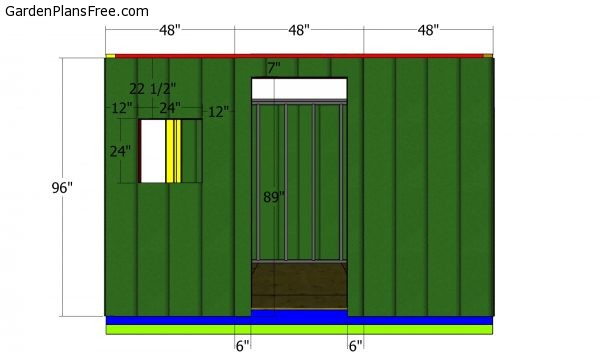

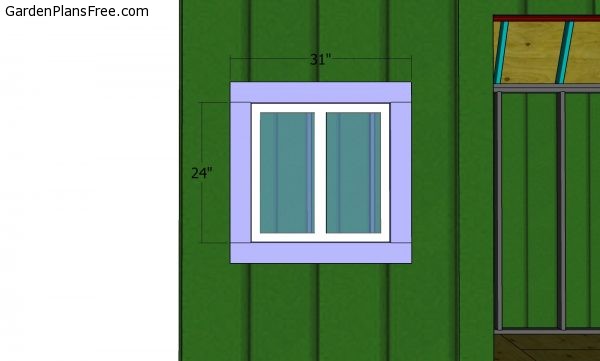

Side wall with door

Add a window opening and a door opening to the opposite side wall frame. As you can see in the diagram, you need to use double 2×4 headers and jack studs for the window. Use 2×6 beams for the double door header. Adjust the size of the opening to suit your needs.

Fit 1/2″ plywood between the double headers and add glue to the joint. Insert 2 1/2″ screws from both sides of the header.

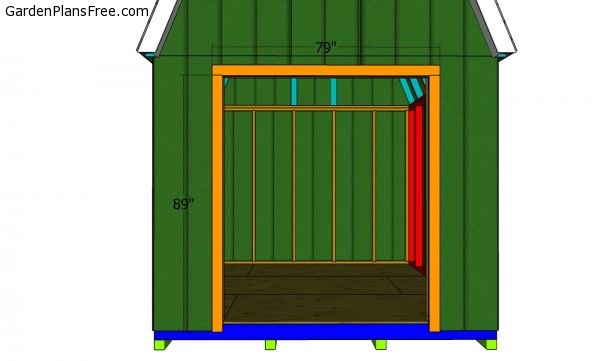

Front wall frame – 10×12 barn shed

Use 2×4 lumber for the front wall frame. Use 2×6 lumber for the double header. You can adjust the size of the door opening to suit your needs. Notice the jack studs that support the double header. The opening is for double 6 ft doors. You can go up to 8 ft with minimal modifications.

Back wall frame

Similarly, build the back wall for the lean to shed, using the same techniques described above.

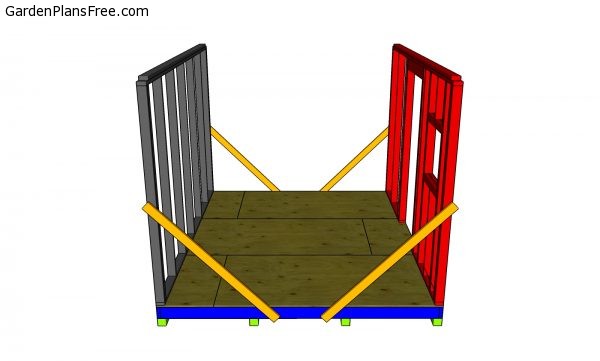

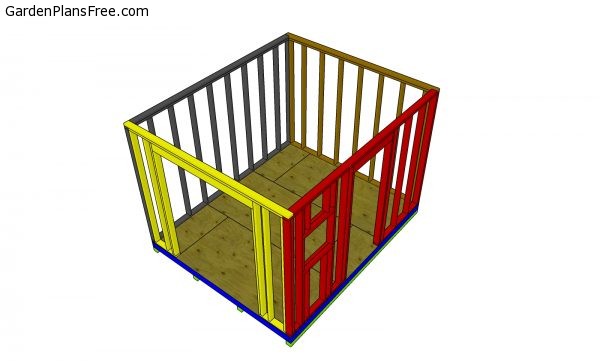

Fitting the side walls

Assembling the frame of the shed

Fit the wall frames to the floor of the 10×12 garden barn shed and plumb them with a spirit level. Drill pilot holes through the bottom plates and insert 3 1/2″ screws into the floor. Lock the adjacent walls together with 3 1/2″ screws. Make sure the corners are square.

STEP 3: Attaching the siding sheets

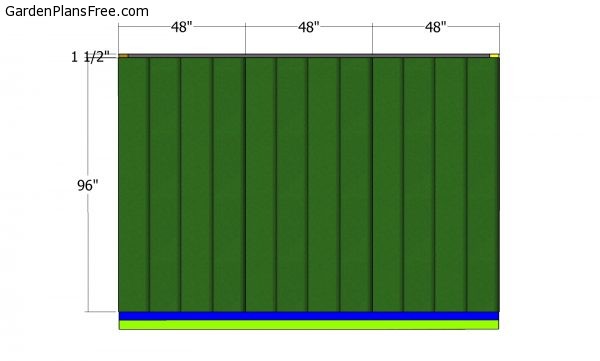

Back wall siding sheets

Attach the T1-11 siding sheets to the back wall of the shed. Offset the sheets 1 1/2″ from the top edge. Leave no gaps between the them. Use 6d nails to secure the sheets to the framing, every 8″.

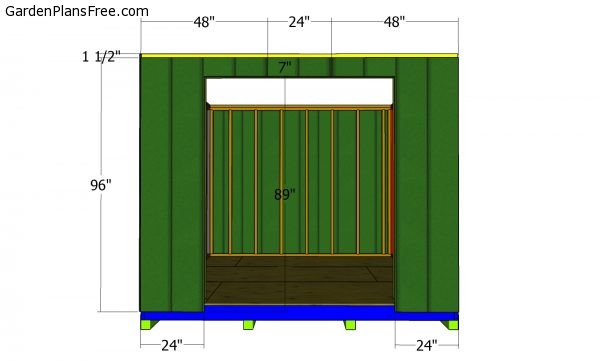

Front wall panels – 10×12 barn

Fit the panels to the front of the shed. Cut out the area that goes over the double door opening. Use a saw to make the cuts accurately. Align the edges as shown in the diagram and use 6d nails to lock the panels into place tightly.

Side wall panels

Attach the T1-11 siding sheets to the side wall. Use a saw to cut out the window and door openings. Leave no gaps between the sheets and use 6d nails, every 8″ along the framing.

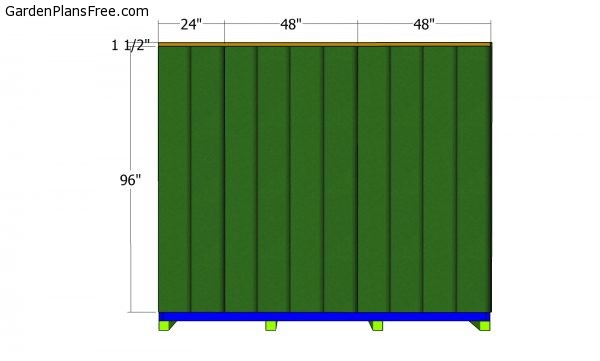

Plain side wall panels

Also, attach the T1-11 siding sheets to the opposite side wall.

STEP 4: Building the gambrel shed roof

Rafters – barn shed

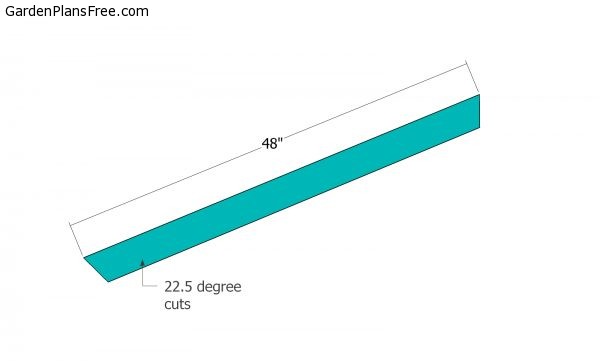

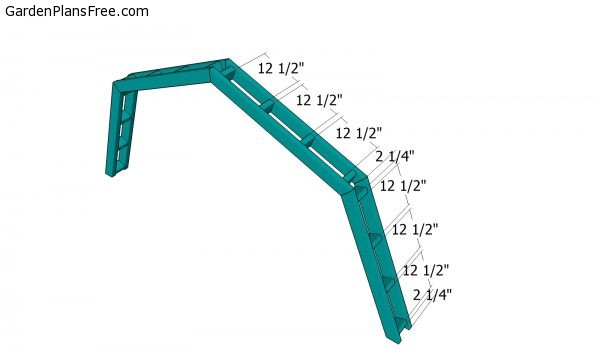

In addition, use 2×4 lumber for the trusses. Use a miter saw to make the 22.5 degree cuts to both ends of the rafters.

Birdsmouth cuts

Next, you need to make a birdsmouth cut to the base rafters, so you can install them to the top of the side walls.

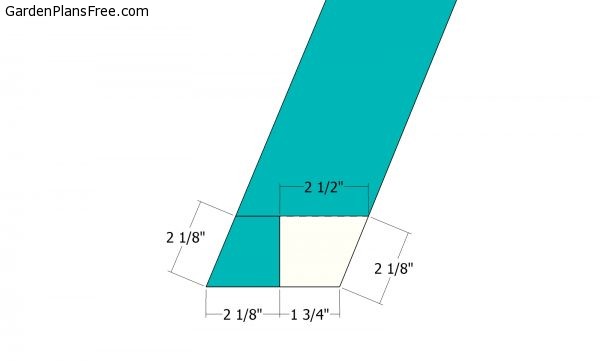

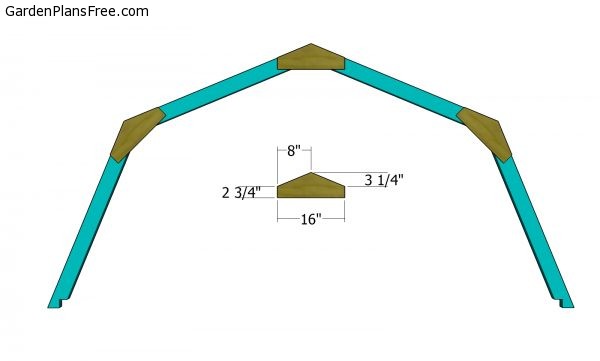

Gussets – gambrel truss 10 ft

Lay the rafters on a level surface and align the edges with attention. Place a straight edge against the base rafters. Use 1/2″ plywood for the gussets and lock them to the rafters with 1 5/8″ screws. Make the gussets as shown in the diagram and lay them flush to the rafters. Alternatively, you can use strong tie plates and 1 1/2″ structural screws to assemble the trusses.

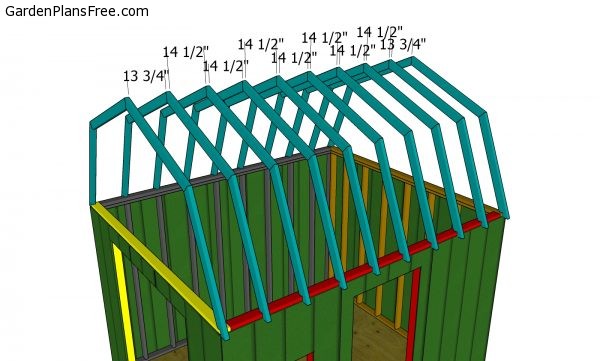

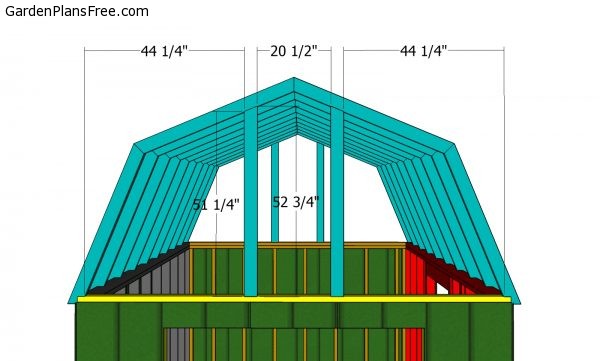

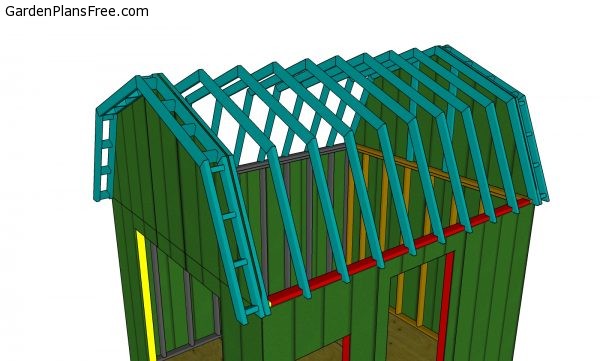

Fitting the trusses to the 10×12 barn shed

Fit the trusses to the top of the shed, every 16″ on center. Use rafter ties to secure the trusses to the top of the storage shed. Use 1 1/2″ structural screws to lock the rafter ties to the top plates and to the rafters.

Gambrel end supports

Fit the 2×4 supports to the gambrel ends. Make the 22.5 degree angle cut to the top of the supports. Drill pocket holes at both ends of the supports and insert 2 1/2″ screws to lock them into place tightly.

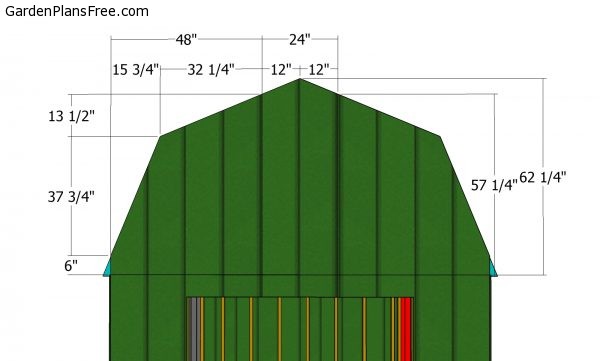

Gambrel end panels

Cut to size and attach the siding panels to the gambrel ends, as shown in the plans. Use 6d nails, every 8″ along the framing, to secure the panels into place tightly.

Assembling the overhangs

Assemble the front and back overhangs using the information from the diagram. Drill pilot holes through the rafters and insert 3 1/2″ screws into the blockings. You can adjust the size of the overhangs by making the blockings shorter or longer. In my case, the blockings are 4 1/4″ long.

Fitting the overhangs to the barn shed

Fit the overhangs to the front and back of the shed. Align the edges with attention and insert 3 1/2″ screws to lock the overhangs to the frame of the shed.

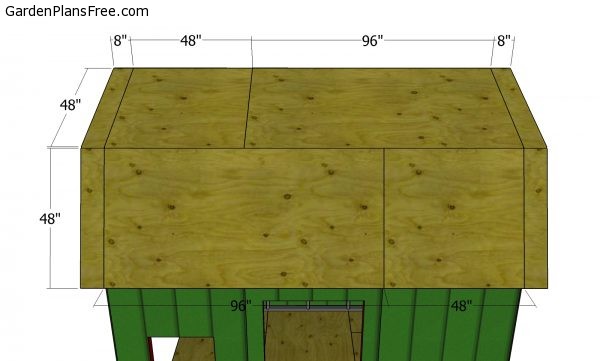

Fitting the roof sheets – 10×12 barn shed

Attach the 1/2″ plywood sheets to the roof of the shed. Start laying the sheets from the bottom up. Leave no gaps between the sheets and insert 1 5/8″ screws, every 8″ along the rafters.

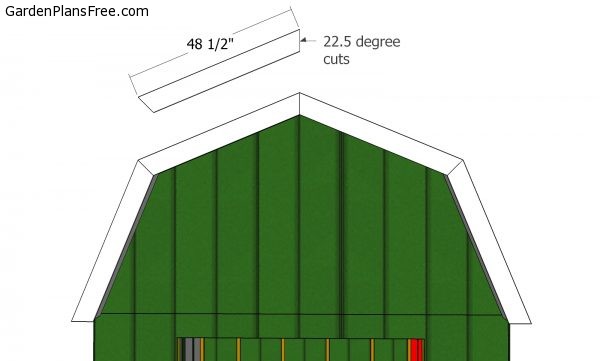

Roof trims

Use 1×6 lumber for the front and back roof trims. Use a miter saw to make the angle cuts at both ends of the trims and then secure them into place with 2″ finish nails.

Fitting the roofing

In order to waterproof the shed, you have to cover the roofing sheets with felt. Make sure the strips of roofing felt overlap at least 2-3″ and staple them to the plywood sheets every 8″. Continue the project by installing the asphalt shingles. Place the starting course at the bottom of the roof, before fitting the rest of the shingles.

PRO TIP: Always read the manufacturer’s instructions, before installing the shingles. They provide essential information about the installation of the shingles.

STEP 5: Building the shed doors

Window trims – 10×12 barn shed

Install the 24″x24″ window to the side of the shed. Next, fit the 1×4 trims around the window to enhance the look of the shed. Use 2″ nails to secure the trims into place tightly.

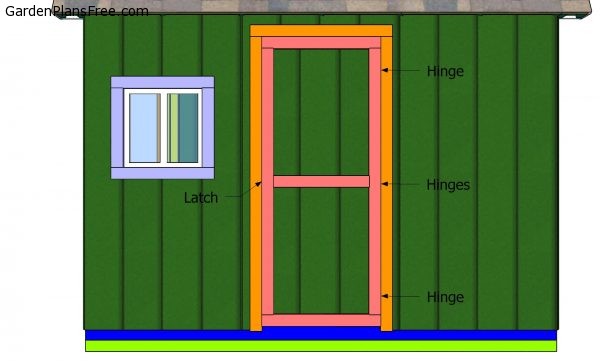

Side door jambs

Also, fit the 2×4 jambs around the side opening. Align the edges with attention and insert 3 1/2″ screws to secure them into place tightly.

Door frame

Next, you need to build the door for the lean to storage shed. Use 2×4 lumber for the frame and T1-11 siding sheets for the panels (the piece that you cut out when attaching the front wall panels). Drill pocket holes and insert 2 1/2″ screws to lock the frame of the door together tightly.

Door panel

Next, lay the trims over the panels and then insert a few 1 5/8″ screws to lock them into place. Turn the door upside down and insert more 1 5/8″ screws through the panels into the trims.

Fitting the side door

Fit the door to the opening and then lock them to the jambs with hinges. Install a latch to keep the door closed and your possessions safe.

Double door jambs

Fit the 2×4 door jambs around the front double opening.

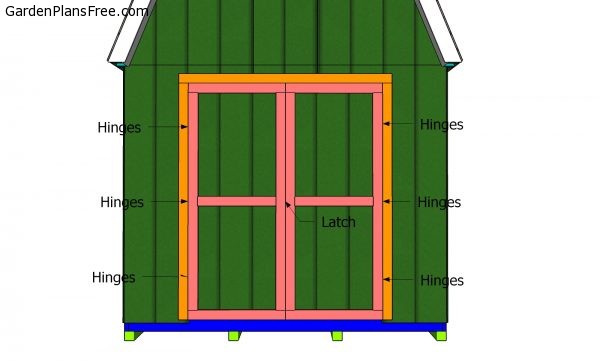

Fitting the double doors

Fit the doors to the front of the shed and lock them to the jambs with hinges.

10×12 gambrel shed

Last but not least, you need to take care of the finishing touches. Apply a few coats of paint over the exterior of the shed. A little paint will get you far in terms of appearance, and it is a relatively small investment. Install the window to the opening and then attach the 1×4 trims around it.

10×12 Shed Plans – Gambrel Shed

You can add decorative trims to the shed to make it pop. In addition, add a vent to make sure the air circulates properly inside the shed.

How to build a 10×12 barn shed

How to build a 10×12 barn shed

You can see all my storage plans HERE. See 10×12 lean to shed plans and 12×16 storage shed plans.

This diy project was about 10×12 garden barn shed plans. If you have enjoyed the free project, I recommend you to share it with your friends, by using the social media widgets.

9 comments

Why can’t I print these plans? What do I need to do to print them?

See GET PDF PLANS button at the end of the article

A cut list should identify which pieces are cut from the purchased lengths. Am I to guess which 2×4’s to cut for the different pieces? A suggested jig for assembling the trusses would be expected. Not impressed

Woodworking is not about guessing it’s about using your mind. I’m sorry your are not impressed by some free shed plans on a blog, but I’m very happy I don’t do this to impress you.

This web page is entitled “gardenplansfree.com/10×12-shed-plans-gambrel-shed-free-pdf-download/”. Note that “Free” appears twice in this web page title. And yet if I try to download these FREE plans it says they cost $4.99. Are they free or is this some kind of bait and switch?

That is not the title of the page, that is the url of the page, the tile is clear – PDF Download. The plans are free, since they are available online. If you want to get the PDF file, you need to support the blog with 4.99, which I consider fair for the quality and level of detail of the plans. If you don’t want to pay for the PDF file, just take the laptop with you in the workshop and you can benefit from my work for free. You also have the option to look for a better deal on other websites. Thank you for the understanding.

At the base of the trusses where it meets the top plate. Is that being left open. Are you adding any blocking in there that I didn’t see or any trim piece to the bottom

You can add blockings between the rafters of you can add soffit to the overhangs on the exterior of the shed.

Would it be possible to use a normal exterior door on this shed?