If you want to learn more about how to build an insulated dog house, we recommend you to pay attention to the instructions described in the video. Work with attention and invest in high quality materials, if you want to get a professional result. It is essential to select the right insulated dog house plans for the size of your pet and for your budget before starting the construction project.

There are many designs to choose from when building an insulated dog house, so make sure you work with attention and plan everything from the very beginning. In this manner you can save time and money, while getting the job done as a professional. Use weather-resistant materials, as the structure will be exposed to moisture and bad weather. Apply a few coats of paint over the components to enhance the look of the dog house.

TABLE OF CONTENTS:

Part 1: Insulated dog house plans

Part 2: Dog house roof plans

Insulated Dog House Plans

Materials

- 1 – 2 pieces of 2×4 lumber – 36″, 3 pieces – 33″ JOISTS

- 2 – 1 piece of 3/4 lumber – 36″x36″ FLOOR

- 3 – 14 pieces of 2×2 lumber – 24″, 4 pieces – 33″, 4 pieces – 36″ STUDS

- 4 – 36 sq ft of insulation board – 54″ INSULATION

- 5 – 2 pieces of 5/8″ plywood – 37″x48″, 2 pieces – 29″x36 WALLS

- 6 – 4 pieces of 1/4″ plywood – 27″x32 1/2″, 2 pieces – 18 1/4″x37 1/4″ INTERIOR WALLS

- 1 piece of ¾” plywood – 4’x8’

- 2 pieces of 2×4 lumber – 8 ft

- 11 pieces of 2×2 lumber – 8 ft

- 2 pieces of 5/8” plywood – 4’x8’

- 2 pieces of 1/4” plywood – 4’x8’

- 1 ½” thick insulation board – 4’x8’

- 100 pieces of 2 ½” screws

- 100 pieces of 3 ½” screws

- 100 pieces of 1 5/8” screws

- 100 pieces 8d nails

- Construction glue

- 20 ft of drip edges

- 15 sq ft of tar paper and asphalt shingles

- paint

Tools

- Hammer, Tape measure, Carpentry square

- Miter saw, Drill machinery, Screwdriver, Sander, Router

- Safety Gloves, Safety Glasses, Respiratory Mask

Time

- One day

Building an insulated dog house

Building the floor of the dog house

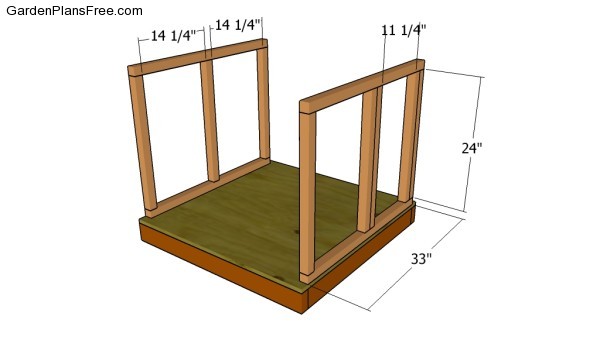

The first step of the woodworking project is to build the floor of the dog house. In order to get a professional result, we recommend you to cut the 2×4 slats at the right size and to lock them together with galvanized screws. Drill pilot holes through the rim joists before inserting the 2 1/2″ galvanized screws to prevent the wood from splitting. Attach the 3/4″ plywood floor over the frame and secure it into place with galvanized screws.

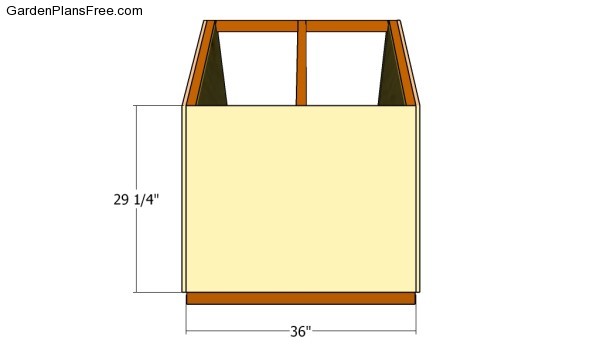

Building the front and the back walls

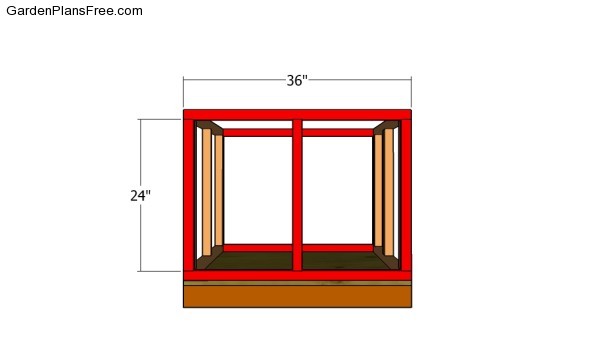

Build the from and back walls out of 2×2 lumber and assemble them together with galvanized screws. Drill pocket holes through the top and bottom plates before inserting the galvanized screws, to prevent the wood from splitting. Plumb the walls with a spirit level before inserting the screws through the bottom plates into the floor.

Building the side walls

Continue the woodworking project by assembling the side walls. Cut the components at the right size and lock them together with 2 1/2″ galvanized screws. Lock the adjacent walls together with screws and add waterproof glue to the joints.

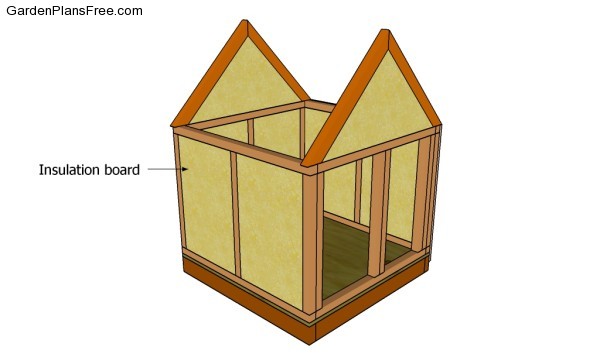

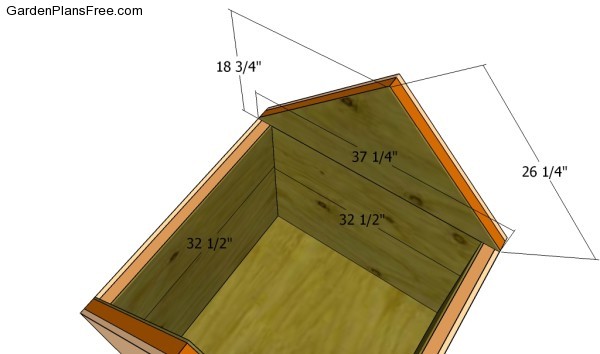

Fitting the boards

Fit the insulation boards between the studs as shown in the plans, cut the pieces of insulation at the right size and fit them into place with attention.

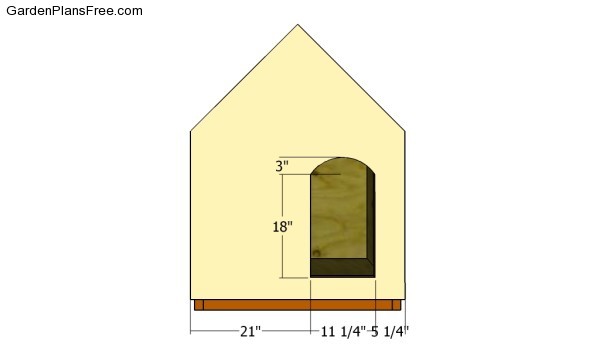

Building the front face

Afterwards, you need to build the exterior walls of the dog house and to attach them to the frame. Use a circular saw to cut the 5/8″ plywood sheets at the right size. Drill a starting hole and make the door opening with a jigsaw. Smooth the cut edges with sandpaper and secure the piece of plywood into place with finishing nails.

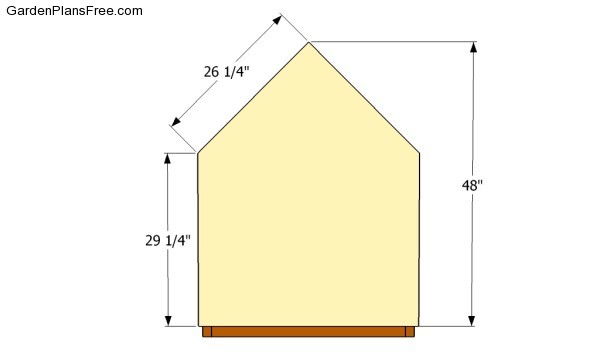

Back wall plans

Build the back face of the dog house in the same manner described above and attach it to the frame with finishing nails. Add waterproof glue to enhance the bond of the components.

Building the side faces

Cut the plywood sheets at the right size, by using a circular saw and secure them to both sides of the dog house frame with finishing nails. Work with attention and make sure there are no gaps between the components.

Fitting the interior walls

Fit the interior walls (1/4″ plywood) and lock them into place with finishing nails. Add waterproof glue to the joints, in order to make them rigid.

Insulated dog house plans

Last but not least, you should take care of the finishing touches. Check if the components are secured into place properly and if the structure is rigid. Make sure there are no protruding screws or sharp edges that could injure you.

PRO TIP: Fill the holes with a good wood filler and smooth the surface with 120-grit sandpaper. Apply several coats of paint or stain over the components, in order to protect them from decay. Take a look over the rest of the project to see how to build the roof of the insulated dog house.

This diy project was about insulated dog house plans free. If you have enjoyed the free project, we recommend you to share it with your friends, by using the social media widgets. LIKE us on Facebook if you want to be the first that gets our latest projects.

<<<< PREVIOUS | NEXT >>>>